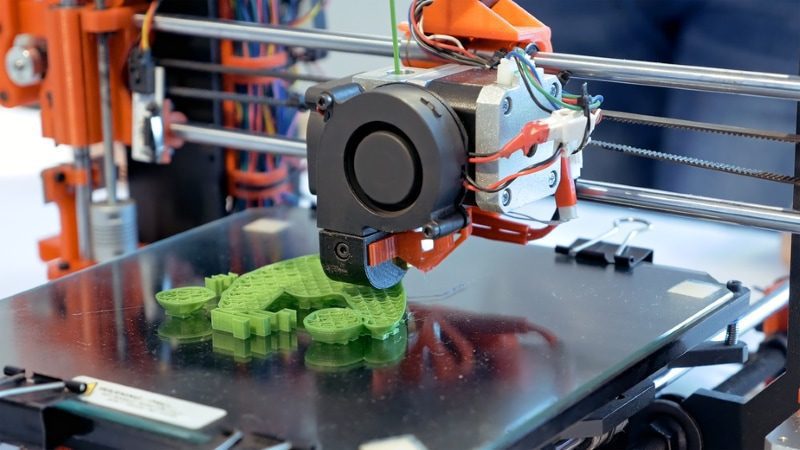

Have you had the opportunity to see any demonstrations of three-dimensional (3D) printing? With 3D printing, layers of a substance are manipulated by computers to create a three-dimensional object. 3D printing used to be something scientists only dreamed of; now it is used routinely in industries like manufacturing, medicine, and engineering.

The first exposure I had to 3D printing came when I read the book Bend Not Break, by Ping Fu. Although elements of the book’s veracity have come into question, my reading of it still exposed me to the science behind the process.

One of our organizational values here at Weaving Influence is flexibility. What does that have to do with additive manufacturing (3D printing’s advanced version)?

Being Flexible Does Not Mean Being Weak

Scientists at the University of Florida used 3D printing to create implanted medical devices that are stronger and more flexible than conventionally produced devices.

In the work world, a value of flexibility has the potential to make us stronger and more flexible. If we come to our roles having preserved our energy in order to concentrate it where it is most needed, we can most effectively serve our customers.

Being Flexible Allows Customization

The scientists mentioned above were able to personalize devices to individual patients through 3D printing. Hero Forge makes intricately designed miniatures with 3D printing.

Weaving Influence is able to respond to varying client needs because we have assembled a multi-talented group of professionals who can respond precisely to client needs. Because of our flexibility, we are able to secure services of people around the world who might not be able to report to a physical office every day but who can contribute from wherever they are.

Lighter Does Not Mean Weaker

As I’ve absorbed more information about additive manufacturing recently, I have learned the term “lightweighting.” It doesn’t exactly mean what I first assumed. When Altair produced a large gantry with additive manufacturing, they were able to reduce the farming component’s weight by 103 pounds without sacrificing strength. Why is that good? A lighter component is easier to transport, relies on less gas, and is less stressful on the human beings having to move it around.

Our organizational value of flexibility helps us perform the services-related equivalent of “lightweighting.” People with definable strengths are able to function efficiently while minimizing administrative drag.

And Then There’s the Mars Example

In his book Spaceman, astronaut Mike Massimino shared his experience making repairs to the Hubble Space Telescope. He and his team had practiced the procedure over and over and over; nothing should have gone wrong . . . until something did. One of the screws they had to unscrew in order to repair a part was stripped and would not budge. Eventually, a roll of tape and a pair of vise grips (no lie – read the book!) saved the day, but Massimino could not drive down to the local Ace Hardware and pick up a spare – he had to solve his problem with only the implements and supplies the mission had taken to space.

Massimino solved his problem; but as NASA works toward its Journey to Mars, what will people do when they need tools or other implements in order to survive?

They’ll PRINT THEM with 3D printing!

Our organizational flexibility allows us to do the same thing: create something that works, efficiently and strongly, when it is needed.

Those kinds of results are out of this world.

Always amazed by the new technologies. It’s exciting to think that 3D printers will be as common as microwaves very soon. Thanks for sharing.

I am too! It’s a bit hard to get my head around but it’s definitely the way things are going. It’s “fun” to think about toys and other luxuries but the potential for the medical field is HUGE and will, I am sure, change lives. Probably save them too.

Paula, My first indtroduction to 3D printing was in fashion! In any case, it is truly fascinating to think of what could and will be done with this technology. So many interesting myths and analogies come about when we start talking about strength and flexibility. As a former yoga teacher, I know that lots of people don’t think that flexible people can also strong. Wrong, you can have both. I’m going to stay tuned to Weaving Influence… Thank you!

Oh YES! regarding yoga. FOR SURE. And in that “Bend Not Break” book, she talks about working for Mattel in the very early days of 3D, and making customized Barbie dolls for her daughter. So many ways to extend this idea. It’s exciting to learn about!